Energy conservation & emission reduction

Energy Optimization Scheme for HAI-FANG Blast Furnace Dust Collector

1、Overview

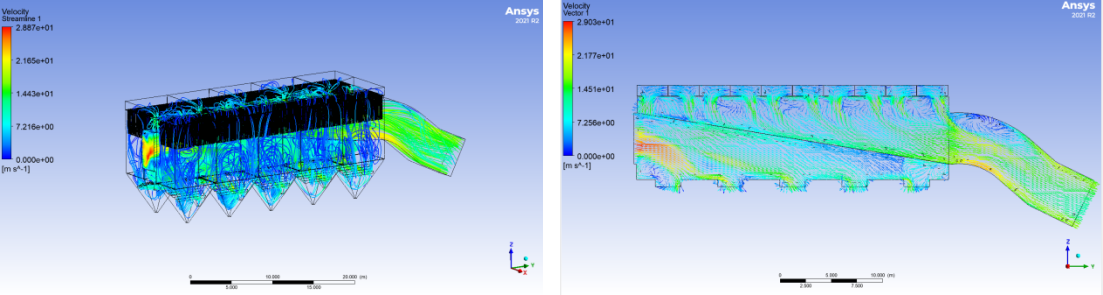

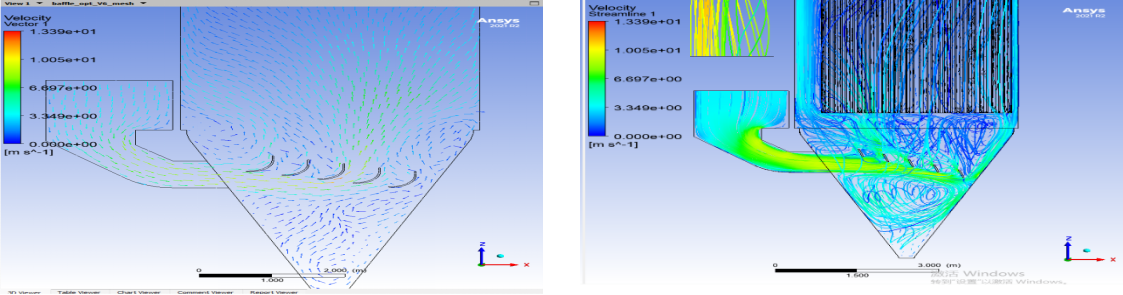

This scheme applies modern CFD methods to simulate flow resistance across sections of the dust removal system, analyzes transport efficiency, and investigates the impact of fan positioning, pipeline layout, and operating conditions on dust removal efficiency and energy consumption. The goal is to optimize dust removal performance, reduce energy consumption, and achieve energy conservation, emission reduction, cost reduction, and efficiency improvement.

2、Implementation Approach

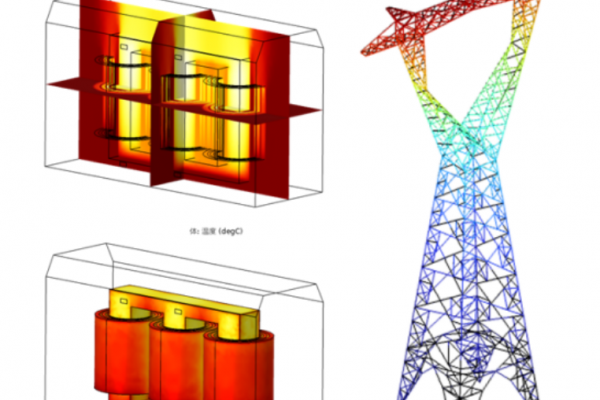

- Build a detailed simulation model of the dust collector to analyze fluid dynamics behavior.

- Study the effects of fan positioning, pipeline layout, and operating conditions on system performance.

- Optimize the topology, location, and quantity of air vents based on simulation data.

- Develop equipment-level energy consumption simulation models to evaluate energy performance.

- Implement energy-saving measures to optimize overall plant-level system efficiency.

3、Objectives

- Adjust vent positions, topology, and quantity to enhance dust removal efficiency and reduce internal flow resistance.

- Optimize pipeline layout and fan configuration to lower energy consumption and reduce input power requirements.

- Improve system operational efficiency, extend equipment lifespan, and minimize material consumption.