Core Modules:

A. Heat Exchange Tube Rapid Generation Module: Generates tube layouts compliant with national standards and supports custom layout file imports.

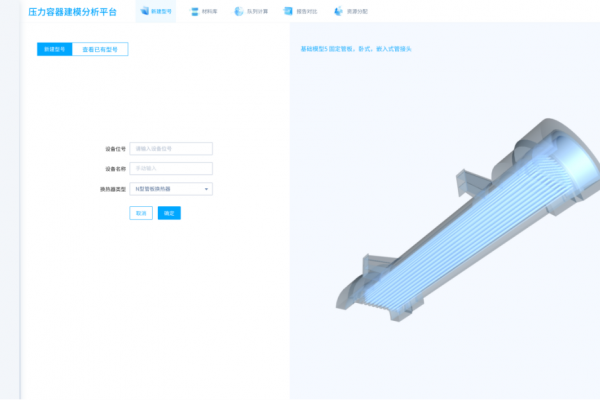

B. Parametric Modeling and Preprocessing Module: Automatically constructs heat exchanger geometry and meshes based on input dimensions and grid parameters.

C. Multi-Condition Simulation Module: Executes customized simulation tasks for pressure vessel heat exchangers and outputs cloud diagrams and linearized path analysis results.

D. Grid Independence Analysis Module: Performs grid sensitivity calculations to assist in determining optimal mesh sizes.

Advanced Modules:

Model management, material management, task queue management, result comparison, and automated reporting.

High Automation: Embeds specialized simulation workflows for pressure vessel heat exchangers, automating meshing, setup, computation, post-processing, and reporting. Reduces 90% of parameter inputs and 80% of manual operations.

Enhanced Efficiency: Utilizes a task queue system to optimize computing resource allocation, increasing non-working hour resource utilization by 300%.

Low Learning Curve: Template-based workflows and built-in expertise allow users to master basic operations in 2 days and full functionalities in 7 days.