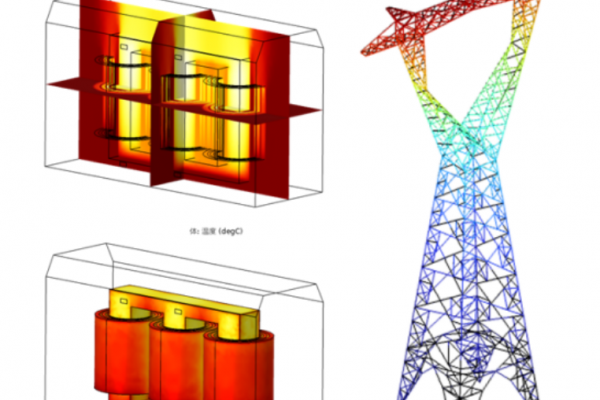

Process-level simulation

HAI Simulation Lithium Battery Electrode Calendering Process Simulation Solution

1、Overview

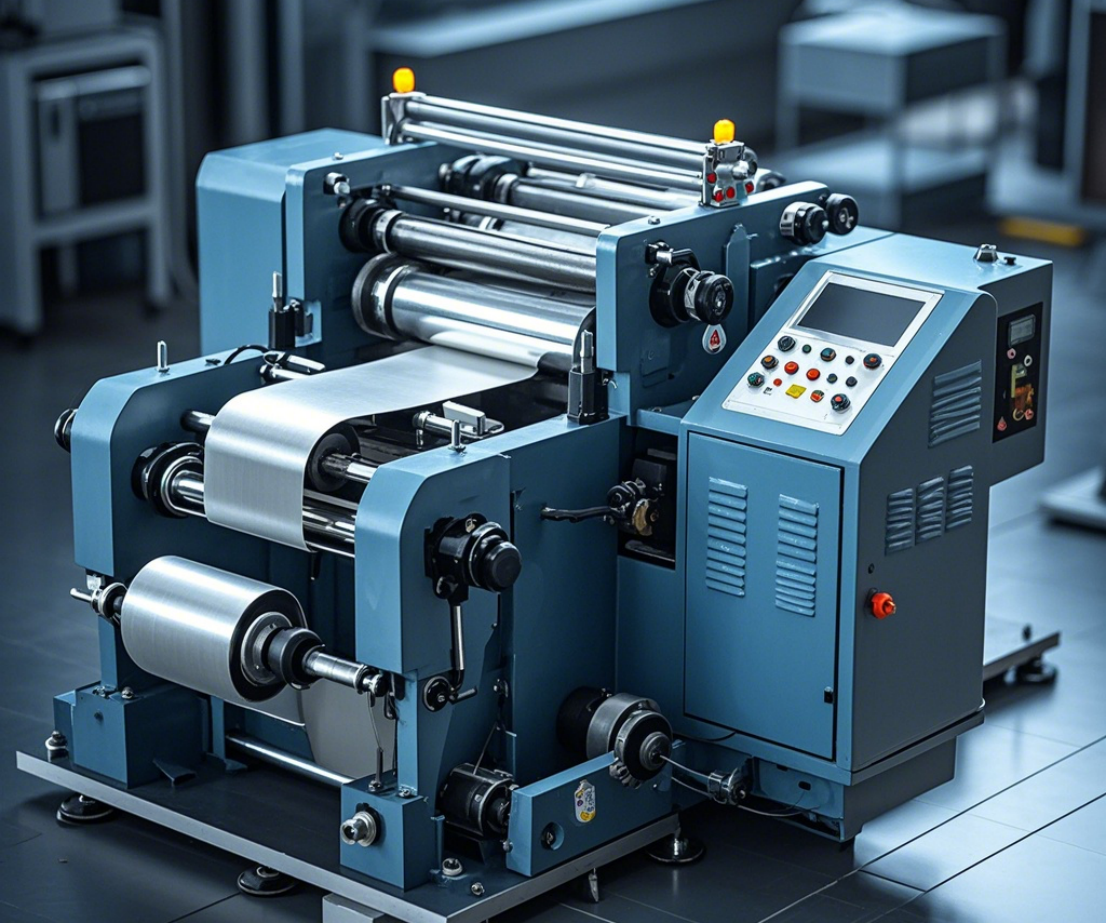

Calendering ensures smooth and flat electrode surfaces to prevent burrs from piercing separators and causing short circuits. It enhances coating density (improving energy density), strengthens adhesion between coatings and current collectors, and reduces active material shedding during cycling. Improper parameters (e.g., roller gap, pressure, unwinding tension) may cause tab wrinkling or web breakage. Simulation tools optimize parameters to eliminate wrinkles, reduce breakage frequency, and enable early warnings.

2、Implementation Approach

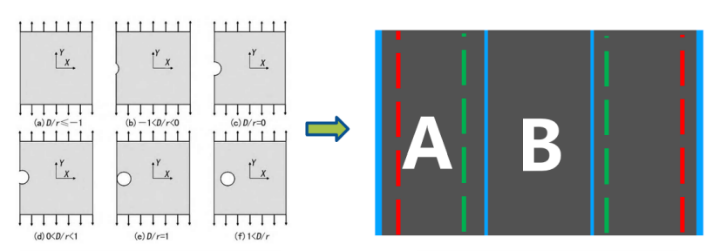

- Tab Wrinkling: Predict buckling caused by compressive stress during calendering using nonlinear buckling analysis and critical buckling load evaluation.

- Web Breakage: Analyze impacts of defect size/distribution on breakage via macro-scale CAE and micro-scale DEM simulations.

极片断带:通过宏观CAE结合微观颗粒DEM的仿真方法,分析单一缺陷尺寸和分布对断带的影响

3、Objectives

- Eliminate tab wrinkling through optimized calendering parameters.

- Reduce web breakage frequency by analyzing defect impacts, saving material costs, and improving production efficiency.