1、Overview

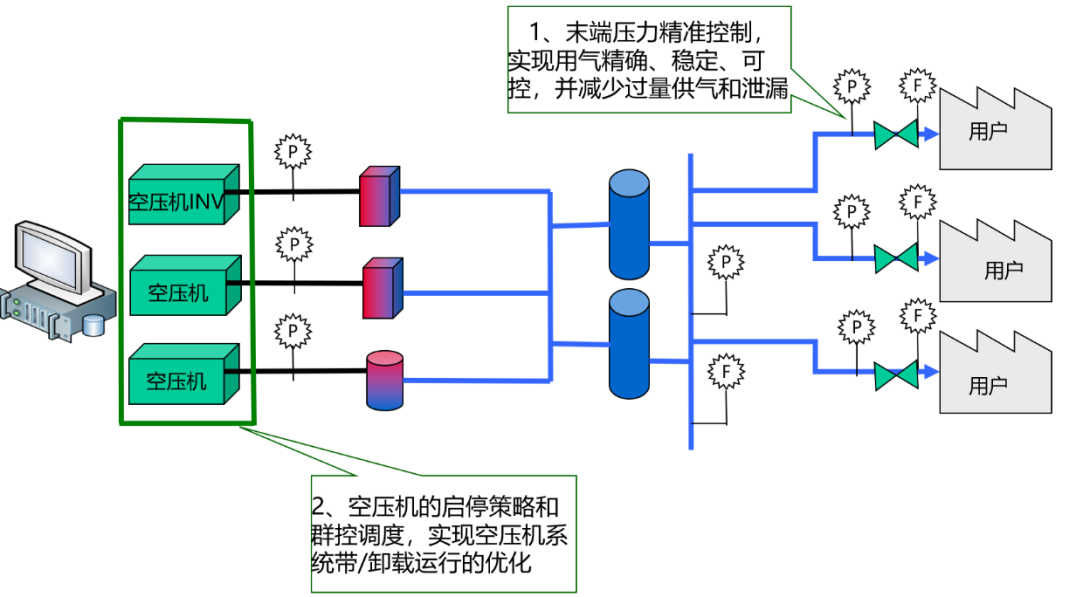

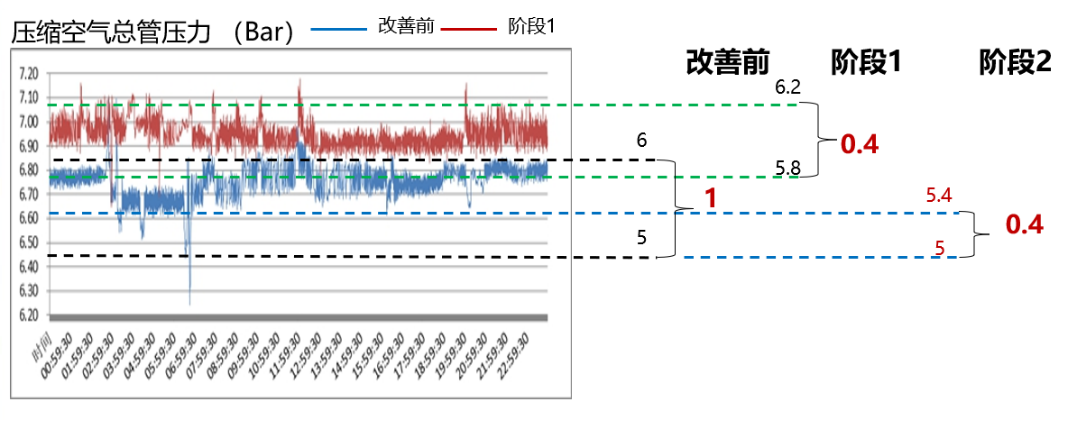

This solution integrates carbon footprint tracking, full-process gas usage analysis, and precision optimization control. Carbon footprint tracking enables real-time monitoring and evaluation of energy consumption across air compressor stations and workshop usage. Gas usage analysis employs mechanistic models of compressed air pipelines to diagnose root causes of pressure fluctuations. Precision optimization control achieves energy savings through terminal pressure reduction and optimized scheduling of air compressor operations.

2、Implementation Approach

The core principle is "precision control," which optimizes the operational parameters of every component in the compressed air system to achieve energy savings and system stability.

3、Objectives

- Energy and Environmental Benefits: Enable real-time assessment of energy consumption and carbon emissions.

- Efficiency Prediction and Alerts: Implement predictive warnings for energy overconsumption and carbon emission peaks.

- Economic Savings: Reduce total pipeline pressure fluctuations by 40%, decrease gas usage and leakage by 8%–10%, and achieve annual electricity savings of 5%–8%.

- Carbon Reduction: Annual electricity savings of 5%–8% translate to a proportional reduction in carbon emissions, as per China’s MIIT standards.