Process-level simulation

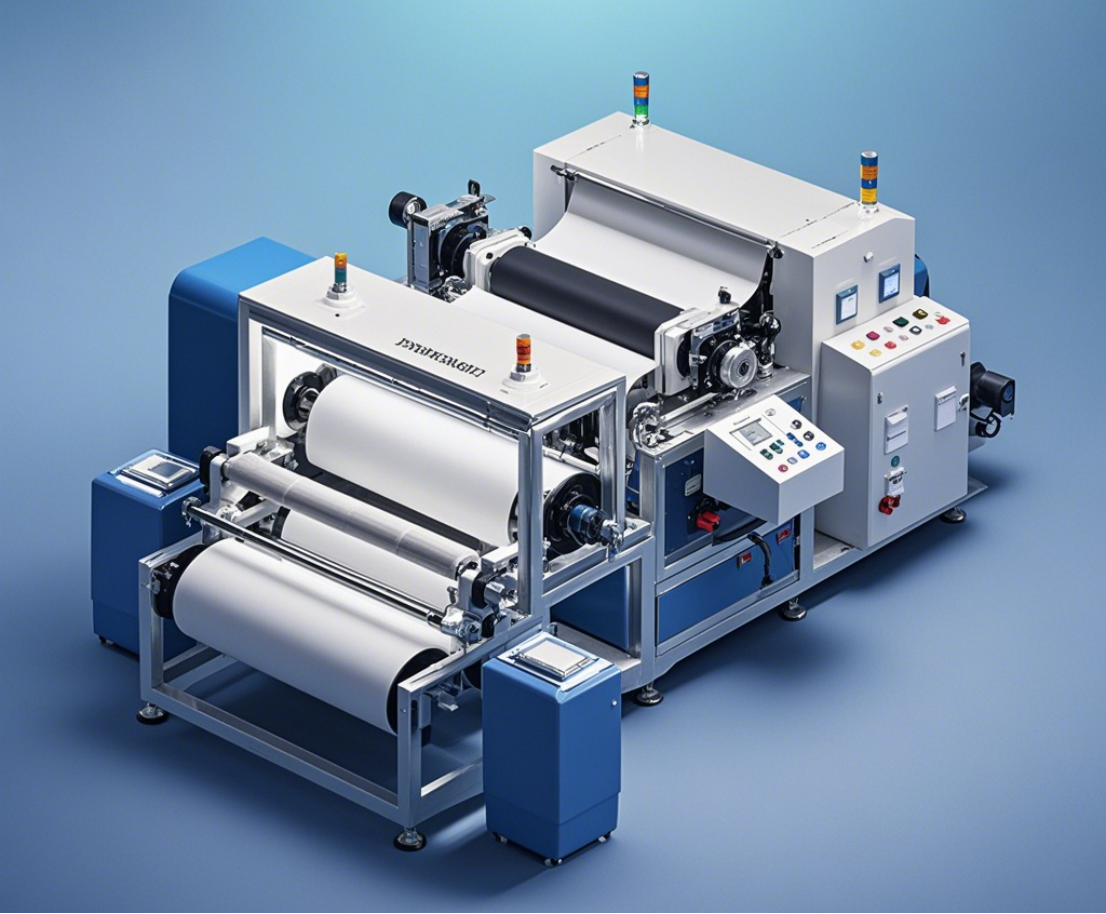

HAI Simulation Lithium Battery Coating and Drying Process Simulation Solution

1、Overview

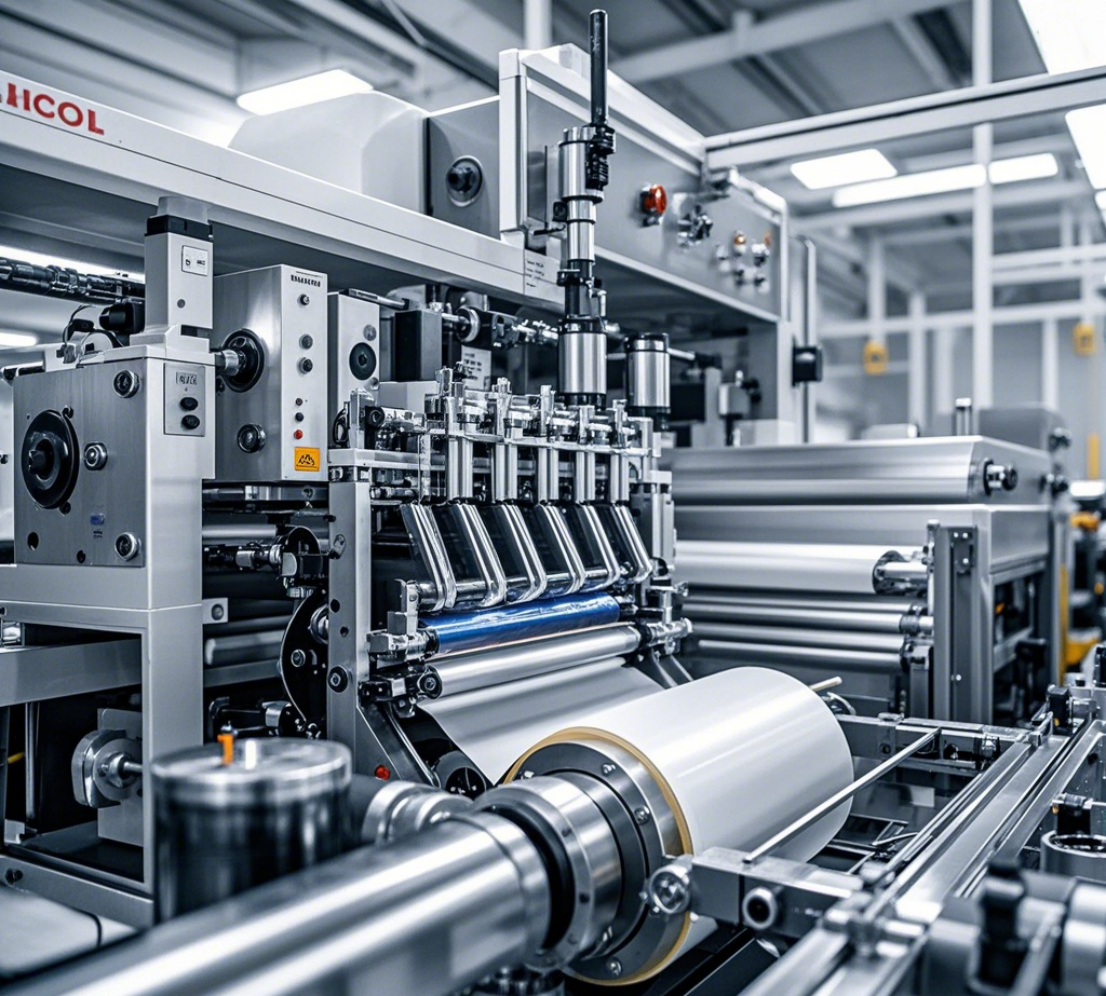

The drying process is a critical step in lithium battery manufacturing, aimed at removing moisture and organic solvents to ensure battery performance and safety. Incomplete drying directly affects downstream processes (e.g., calendering adhesion issues, inconsistent compaction density), leading to reduced capacity, shortened cycle life, and safety risks. Precise drying parameters are essential for electrochemical performance and long-term stability.

2、Implementation Approach

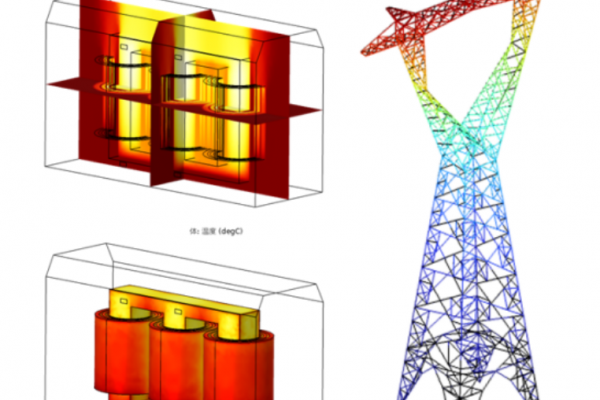

- Dual Technical Approaches for Drying Mechanism Analysis:

- Microscopic Level: Electrode sheet drying mechanisms, shrinkage, and solvent diffusion.

- Macroscopic Level: Flow/temperature field uniformity and reducing flow resistance in drying ovens.

3、Objectives

- Reduce Energy Consumption: Optimize drying strategies to improve efficiency and lower energy use.

- Enhance Data Consistency: Improve post-drying electrode thickness and binder content uniformity.