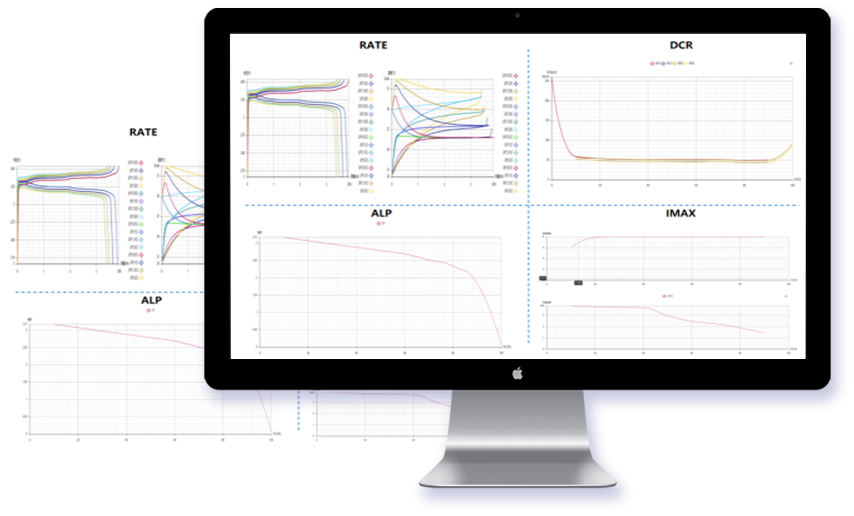

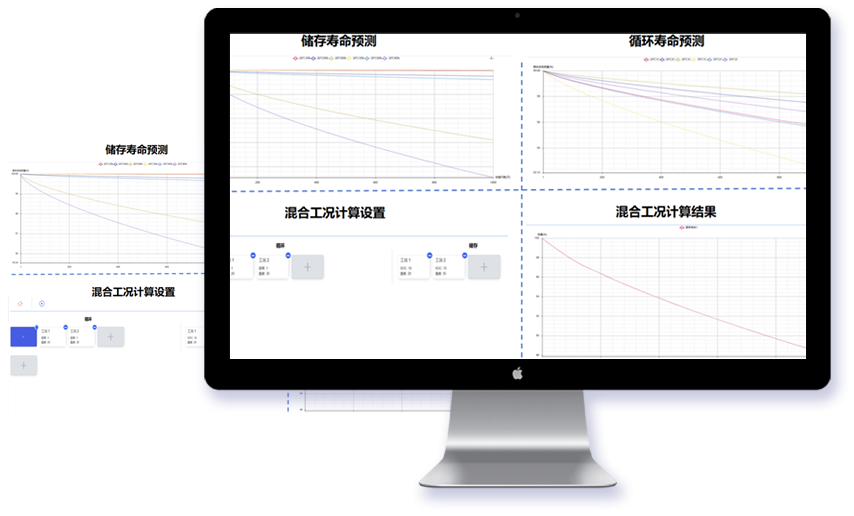

Simplified potential calculation PDEs in traditional P2D models (6-8× speed improvement)

Multi-parameter identification algorithm (2-3× faster than existing methods)

Material parameter classification system (static physical parameters vs dynamic parameters) enhances design efficiency/accuracy

China's first equivalent circuit-based P2D algorithm for Li-ion cells enables material compatibility optimization

High accuracy: <0.5% error (single condition), <1% (cross-condition)

Ultra-fast computation: 5s for 1500 cycles, 1ms per data point

Flexible deployment: Supports CPU/GPU (RTX3090 recommended for cross-condition)

Strong generalization: AI models adapt to new data scenarios

Multi-scenario application: Compatible with automotive BMS and industrial systems

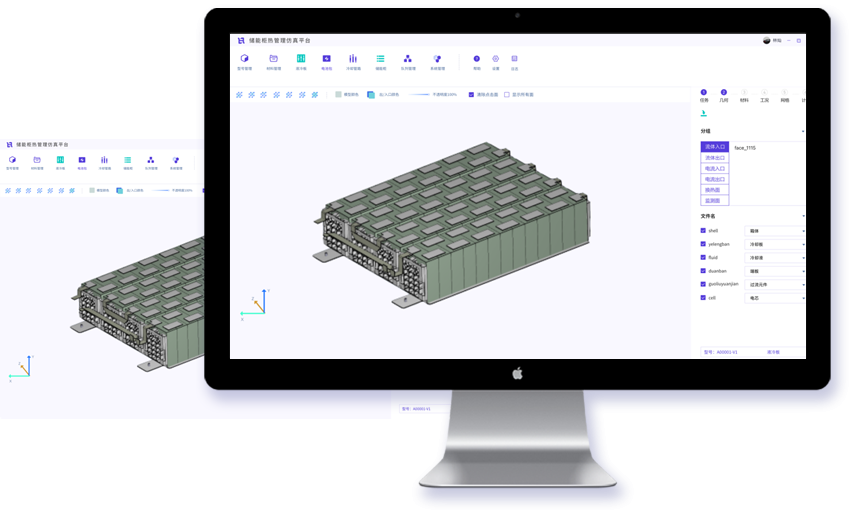

90%+ reduction in mesh generation time

4-5 orders of magnitude efficiency improvement vs conventional fluid simulation

Cost-effective alternative to physical testing

Enterprise-ready solution for optimized battery manufacturing design

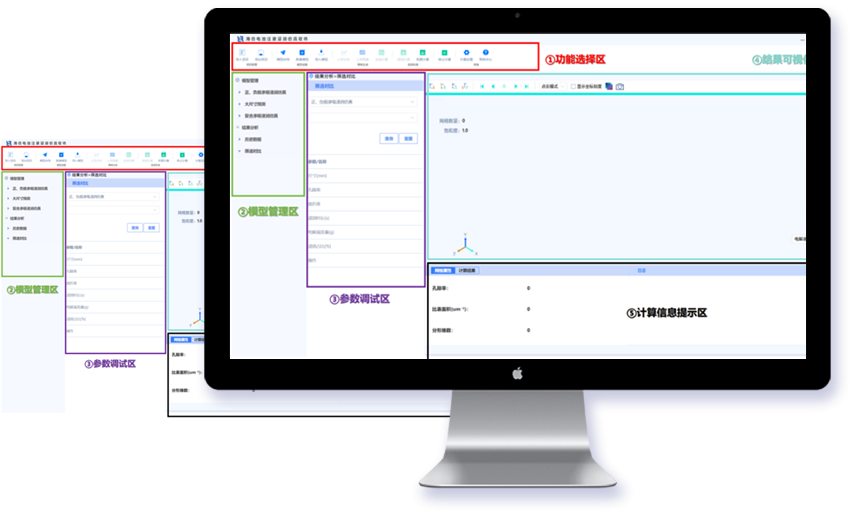

Integrates simulation mechanism models with AI deep learning algorithms for efficient model calibration. Enables real-time thickness monitoring with early anomaly detection, dynamic simulation visualization, and data-driven decision support for coating process optimization.

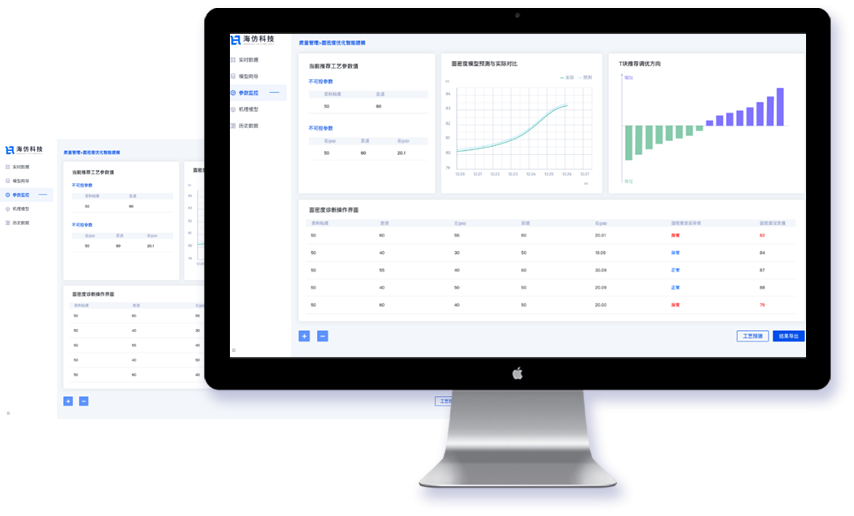

Merges electrochemical models with machine learning for accurate capacity prediction and early defect detection. Provides visualization of simulation results and production analytics, significantly improving energy efficiency and reducing capital expenditure in capacity grading processes.

High Automation: End-to-end automated workflow reduces parameter inputs by 90% and manual operations by 80%

Efficiency Enhancements: Batch task generation and queue management cut idle time by 95%, with 300% improvement in off-hour resource utilization

Low Learning Curve: Template-based workflows enable proficiency in 2 days for experienced engineers, 7 days for novices

Integrated Simulation Platform: Ensures closed-loop process data flow to avoid computational errors caused by data transfer between multiple simulation tools.

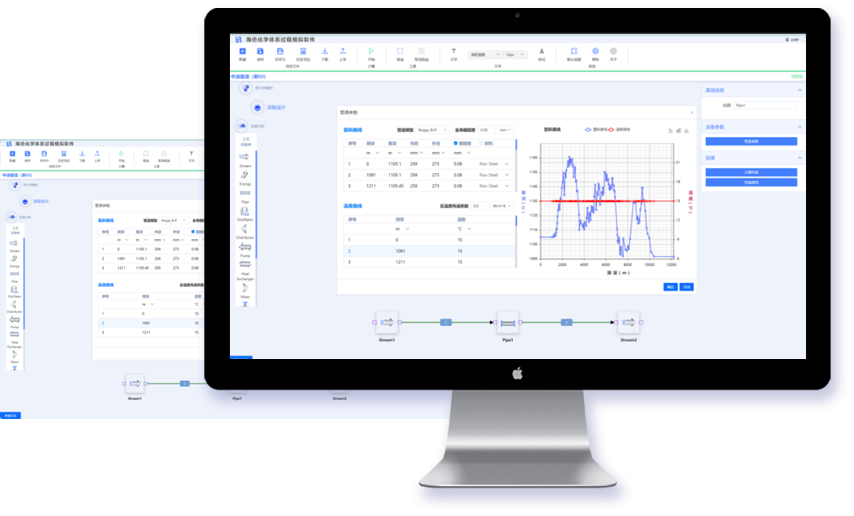

User-Friendly Process Modeling: Offers 2D process flow modeling with drag-and-drop functionality for quick workflow setup.

Distributed Architecture: Innovatively enables online collaboration for petrochemical production design simulations, improving efficiency.

High Efficiency and Stability: Rich library of solving algorithms ensures fast and stable computations.

User-Friendly Interface: Simplified operation with AI-driven automatic parameter optimization.

Electrochemical Simulation Integration: Delivers physically accurate thermal simulations for battery packs and energy storage systems.

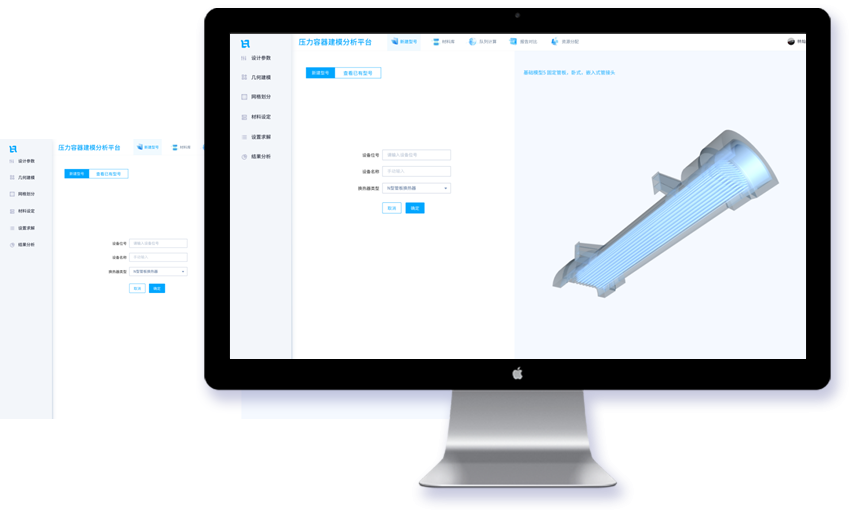

High Automation: Embeds specialized simulation workflows for pressure vessel heat exchangers, automating meshing, setup, computation, post-processing, and reporting. Reduces 90% of parameter inputs and 80% of manual operations.

Enhanced Efficiency: Utilizes a task queue system to optimize computing resource allocation, increasing non-working hour resource utilization by 300%.

Low Learning Curve: Template-based workflows and built-in expertise allow users to master basic operations in 2 days and full functionalities in 7 days.

High Efficiency: 2.5× faster than standard optimization workflows through six innovations

Universal Deployment: Compatible with any simulation software, boundary conditions, and solvers

Flexible Optimization: Supports both global (e.g., Cl) and grid-level (e.g., u) objectives

Smart Algorithms: CFD Warm-start acceleration, auto parameter range definition, and advanced sampling

Lightweight Visualization: 8-10× data reduction through precision optimization and layered processing

CAD-CAE Fusion: Spatial alignment of geometric models with CAE results

Smart Resource Scheduling: Automated task allocation for improved hardware utilization

Batch Processing: Multi-case parameter batch input and task creation

多平台展示、多软件兼容、多软件CAE结果对比

大大减少硬盘空间的占用,降低了存储成本

大幅缩短等待时间、操作时间,用户体验好